Line Balancing Is Best Used in Which Type of Layout

Line balancing technique was used normally in assembly line of the automotive industry which is called ALB. Please do so.

Lean Line Balancing In The It Sector

Layout which the product or project remains stationary and workers materials and equipment are moved as needed.

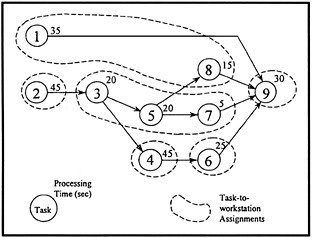

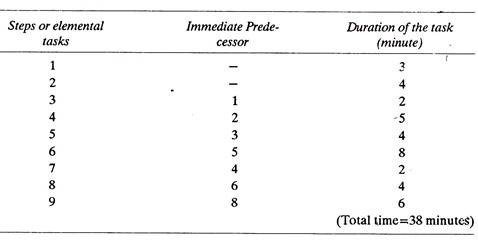

. Assembly line design and balancing Designing and balancing the Audi B9 Mirror assembly line at SMR Automotive Mirrors Technology Mosonszolnok Hungary Master of Science Thesis in the Masters programme Production Engineering RANJITH RAJA Department of Product and Production Development Division of Production Systems. Facility layout t ool changes. Balancing and sequencing problem varies with the types of AL s.

10 Any one cell layout is only suitable for making one specific product. Identify tasks whose predecessors have been assigned to a workstation available tasks. Process Functional layout B.

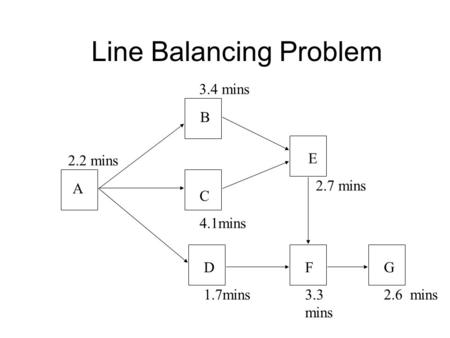

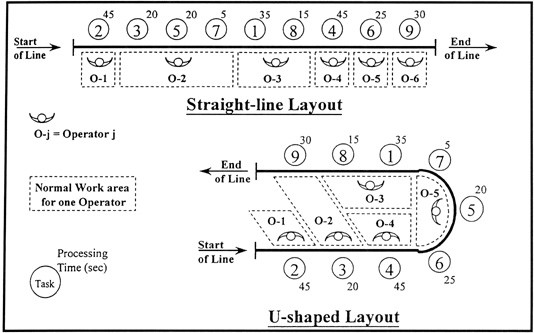

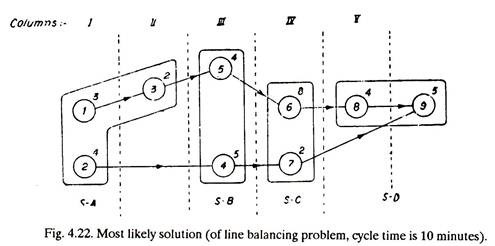

LINE BALANCING The goal of a product layout is to arrange workers or machines in the sequence that operations need to be performed. The newly designed line will then appear on the layout as depicted below. Line Balancing Heuristics Methods used to develop solutions for product layout problems.

Incremental Utilization Heuristic adds task to a workstation one at a time until 100 is utilized 2. The sequence is referred to as a production line or an assembly line. Buy These Notes in PDF Format There are two types of line balancing that include Static Balance and Dynamic Balance.

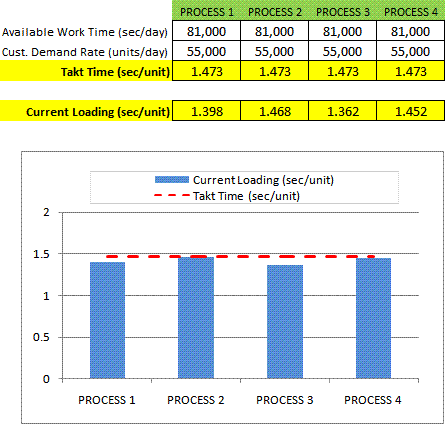

In the context of line balancing the lines capacity is _____. 12 Cycle time can be calculated by dividing total work content by the number of stages in a line layout. Line balancing involves assigning tasks to workstations.

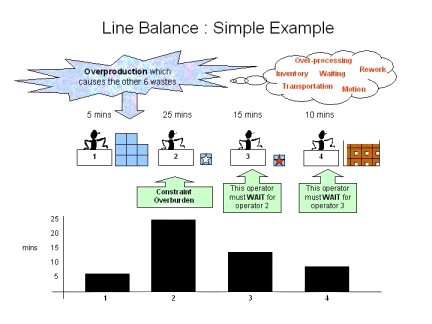

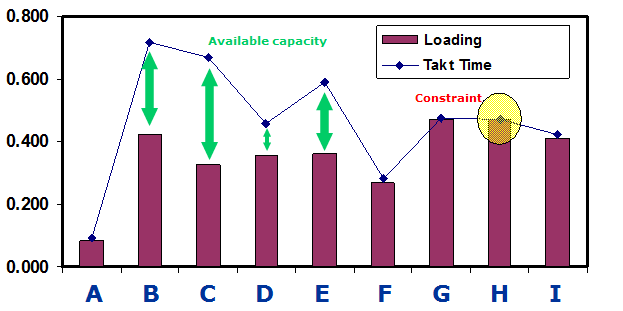

Line Balancing Line Balancing in a layout means arrangement of machine capacity to secure relatively uniform flow at capacity operation. A constraint slows the process down and results if waiting for downstream operations and excess capacity results in waiting and no absorption of fixed costs. 16 _____ A Line layout B Cell layout C Functional layout D Fixed-position layout 17 Match the following statement to the layout type Plant and staff move to the work.

A SIMPLE ALGORITHM 1. Select the best definition of line balancing in the context of product layouts. We start out with Station 1.

It can also be said as a layout which has equal operating times at the successive operations in the process as a whole. Product layout requires line balancing and if any production line remains unbalanced machinery utilisation. Most of the Small and Medium Industries do not use line balancing method in the production line.

But it could be the best available design according to the process precedence rules. Product or straight line layout means the arrangement of production equipment in the order of manufacturing operations. Meaning of Line Balancing.

Longest Task Time Heuristic where the task that takes the longest time is added in the precedence diagram. Information in this step about the tendencies of the line to be implemented. It can also be said as a layout which has equal operating times at the successive operations in the process as a whole.

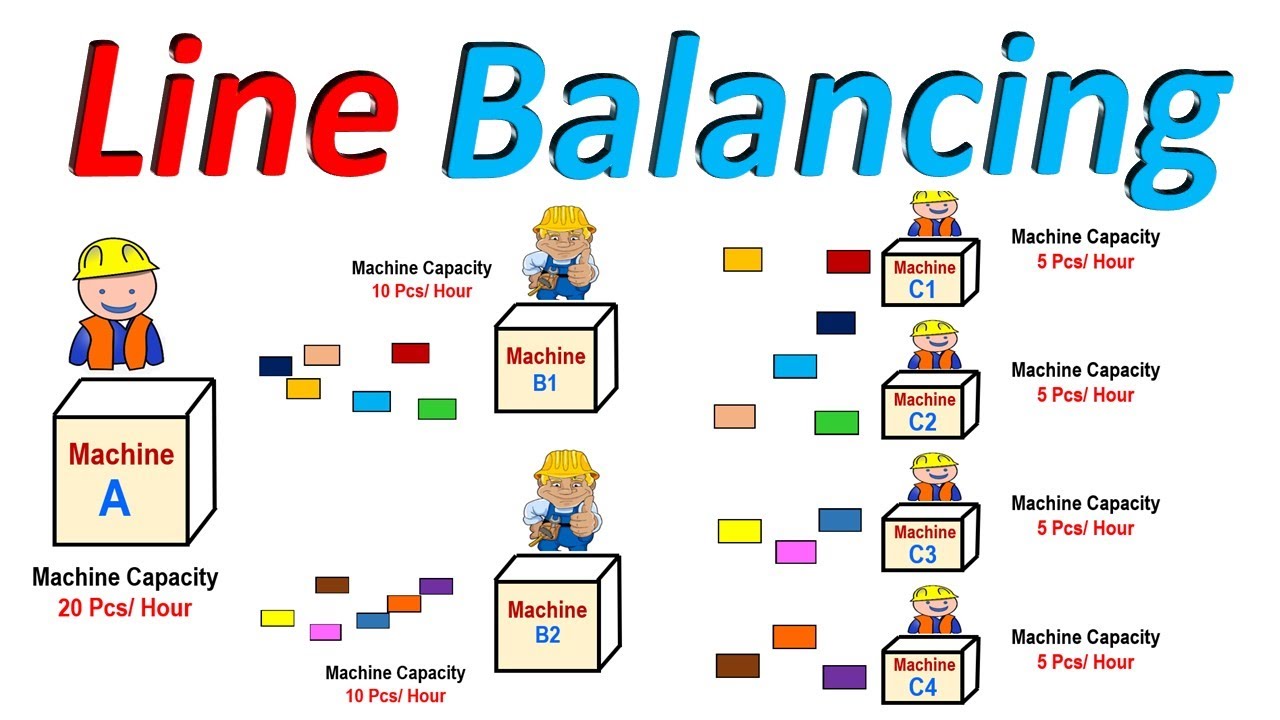

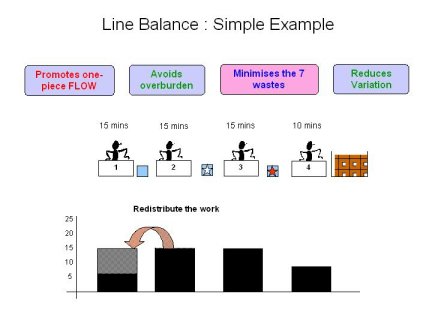

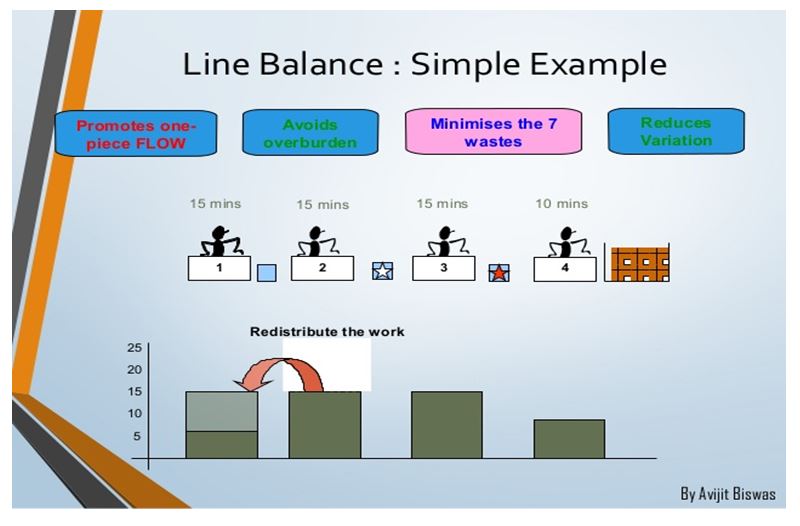

If you duplicate the process in parallel your target line for an individual process doubles or your combined cycle time divides by two. Line balancing is a production strategy that involves balancing operator and machine time to match the production rate to the takt time. Line Balancing in a layout means arrangement of machine capacity to secure relatively uniform flow at capacity operation.

We can see that Station 4 is under-cycle with 236 seconds of idle time. 17 _____ A Line layout B Fixed-position layout C Cell layout D Functional layout 18 Match the following statement to the layout type Best for low volume high variety. Takt time is the rate at which parts or products must be produced in order to meet customer demand.

The key Line Balancing steps we will focus on are. For instance single model line produces a single product over the line. Line balancing is a process in manufacturing to create the layout of a production line to distribute the workload at various manufacturing stations to achieve the best talk time.

For landscaping a home which layout type would be used. Here the takt time is product manufacturing time to fulfill customer demand. Line layout is intended to effect an orderly and logical arrangement of productive facilities that will be consistent with large production volume.

Product or Line Layout. For a given production line if production time is exactly equal to takt time then the line is perfectly. The process of assigning tasks to workstations in such a way that the workstations have approximately equal time requirements.

Determine from available tasks those that fit ie those whose tasks times time remaining to be filled at this work station. 11 Line balancing is used to attempt to equalise the work time content of each stage of a line layout. Line Balancing in Manufacturing Defined.

Line Balancing is leveling the workload across all processes in a cell or value stream to remove bottlenecks and excess capacity. Similarly if you triple or quadruple the processes so does the target or alternatively the cycle time reduces to a third or a fourth.

Line Balancing Tool Based On Operator Skill Matrix

What Is Line Balancing How To Achieve It Tulip

U Shaped Assembly Linesu Shaped Assembly Linesin Straight Vs Springerlink

Assembly Process Planning Proplanner

𝐋𝐢𝐧𝐞 𝐁𝐚𝐥𝐚𝐧𝐜𝐢𝐧𝐠 Production Line Balancing Assembly Line Balancing In Operations Management Youtube

Line Balancing Problem Ppt Video Online Download

Modified Product Layout And Assembly Line Balancing Example Youtube

U Shaped Assembly Linesu Shaped Assembly Linesin Straight Vs Springerlink

What Is Line Balancing How Can It Help You Here Are The Answers

Line Balancing And Its Methods Industries

What Is Line Balancing How Can It Help You Here Are The Answers

Line Balancing And Its Methods Industries

Operations Management Studiousguy

Line Balancing Software Generates Assignment Of Tasks To Operator Proplanner

Comments

Post a Comment